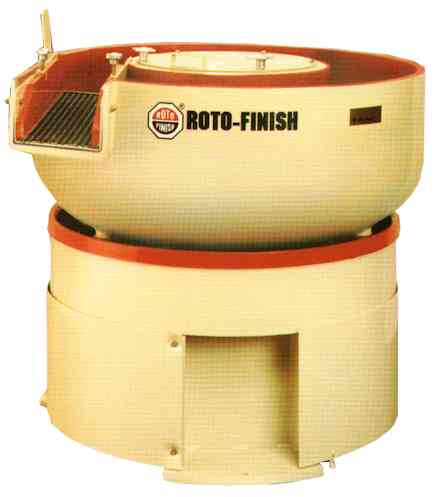

Microsheen was first established with our

outstanding deburring capabilities, and has

grown steadily from this solid base.

If you are a

parts manufacturer, whether you

produce metal, plastic, stamped, cast, extruded

or machined parts, you can benefit by utilizing

our deburring facilities.

Burrs, sharp

edges, tool marks, flashing,

heat-treat scale, and rust can be removed with

precision controlled techniques.

Polishing,

generating radii, and surface

improvement (if required or desired) can also be

achieved in large or small production quantities.

|

|